Packaging / Product Information

Dangerous goods are articles or substances that are capable of posing a significant risk to Health, Safety, Property or the Environment and which are listed in Dangerous Goods Regulations. There are over 700 individual hazardous goods listings within the dangerous goods regulations.

Read our Did you know these items were dangerous? for more information.

The transport of dangerous goods is subject to modal regulations that follow the Recommendations of the U.N. Committee of Experts on the Transport of Dangerous Goods (commonly referred to as ‘The Orange Book’). The relevant authorities for the various modes of transport available are:

1. The International Civil Aviation Organisation for the transport of dangerous goods by air

2. International Maritime Organisation for hazardous goods by sea

3. ADR/RID regulatory guides for transporting dangerous goods by road and rail through Europe.

Each of these regulatory guides spells out the legal position and associated responsibilities of a shipper.

Despite ICAO producing the regulatory statements for transporting dangerous goods by air, the more commonly used guides are produced by IATA (The International Air Transport Association).

Read our Understanding UN Regulations article for more information.

For each United Nations approved package there is a test certificate, which is issued by a state and details:

- The name of the body that the certification is issued to (Quite often this is the manufacturer).

- The packaging type – for example, 4G, 1A1 or 3H2.

- Material information; including the type of material used – for example, corrugated fibreboard or steel.

- Any closure methods – for example 50mm tape.

- If inner packagings were used, then the quantity contained within them.

- The packaging tests that were applied; drop test, stack test, etc.

- The packing group(s) that the packaging is approved for – I, II or III.

- The UN approval mark.

- Conditions of issue (usually found on the back of the certificate.

In order to remain compliant, the packaging must be used in exactly the same way as it was tested and approved.

Class 1: Explosives

Class 2: Gases

Class 3: Flammable liquids

Class 4: Flammable solids

Class 5: Oxidising agents & organic peroxides

Class 6: Toxins and infectious substances

Class 7: Radioactive material

Class 8: Corrosives

Class 9: Miscellaneous dangerous goods

Want to know more? read our Categorising Dangerous Goods article

Packaging which has been designed, tested and certified to enable the safe transportation of Dangerous Goods. The packaging itself will have passed sufficient tests stipulated in the relevant DG regulations, which means the manufacturer designing the packaging must adhere to strict guidelines and ensure the packaging passes a number of tests in order to prove it can provide the safe transportation of the dangerous goods. To gain UN approval, the manufacturer’s package is sent to and tested by an independent testing company, if the packaging successfully passes the tests, it is then sent for verification to the relevant state approval authority for approval and then assigned a UN Mark which is printed on the packaging.

Read our UN Approved Packaging Explained article for more information.

Simply put, no. Not all packaging used for transporting dangerous goods must bear a UN approval mark. There are some packagings that do not require a UN mark but do still need to meet a number of requirements set out in the model regulations, including their capability of passing various packaging tests and the quality of material used. Limited Quantity, Excepted Quantity and Packaging for Biological Substances (Class 6.2 Category B Infectious Substances) are examples where packaging does not need to bear a UN Mark but needs to conform to various construction and capability standards outlined in the relevant DG regulations.

You can identify whether or not a substance or material requires UN approved packaging by looking at the relevant packaging instruction for the associated UN number.

Dangerous goods packaging differ considerably to everyday packaging, such as household boxes used to store and general transport. For example, Certified Dangerous Goods packaging has been designed and tested to prove it is capable of withstanding the normal conditions of transport. There are specific measures that must be taken to ensure that, should a package containing dangerous goods fall from a shelf or wagon, that the substance or materials inside remain safe to limit the likelihood of harm.

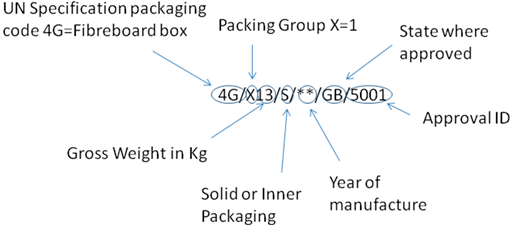

A UN specification mark indicates that the packaging it corresponds to has been approved to United Nations standards for the transport of dangerous goods by road, sea and/or air. It does not necessarily indicate the use of the packaging in correspondence to any particular substance. A UN specification mark will usually be made up of a number of numbers and letters, directly following a ‘UN’ logo. The below is an example of a UN specification mark that would be displayed on an approved fibreboard box – known as a 4G package.

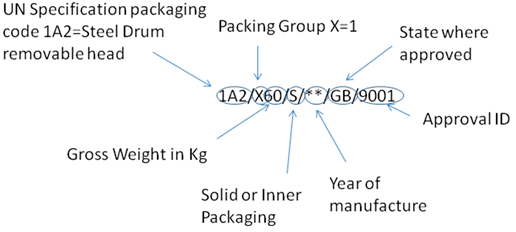

Similarly, the next example relates to a UN approved steel drum with a removable head – given the UN packaging type identification ‘1A2’.

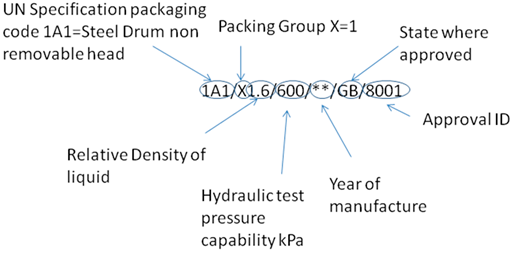

The same drum (with a non-removable head) has a different UN mark – note the ‘1A2’ identification for a removable head shown above is now changed to the ‘1A1’ for a non removable head as below. This example also specifies it is approved with liquids, with the exclusion of the ‘S’ and inclusion of the density and pressure capability information. Note; when no density of liquid is shown then it is assumed it’s 1.2 density.:

You can read more about UN Marks here

Packaging Type Code

1 – Drum

2 – Reserved

3 – Jerrican

4 – Box

5 – Bag

6 – Composite Packaging

Packaging Material Codes

A – Steel

B – Aluminium

C – Natural Wood

D – Plywood

F – Reconstituted Wood

G – Fibreboard

H – Plastic material

L – Textiles

M – Paper, multi-wall

N – Metal

P – Glass

Packaging Qualifying Codes

The letter ‘V’ following the packaging code signifies a “special packaging” conforming to a specific set of requirements as set out in the relevant regulations

W signifies: that the packaging, although of the same type indicated by the code, is manufactured to a specification different from that in subsection 6.2 (IATA) or as set out in the relevant regulations

U signifies: signifies a special packaging for infectious substances conforming to specific requirements stated in the relevant regulations.

T signifies a “Salvage Packaging” conforming to a specific set of requirements as set out in the relevant regulations

Openings 1 and 2

Openings relate to whether the head is ‘non removable (1)’ or ‘removable (2)’. Example = ‘1A1’ for a non removable head and 1A2’ identification for a removable head.

UN Packing Groups?

X = I

Y = II

Z = III

Which packing group is the most dangerous?

• Packing Group I (X): high danger.

• Packing Group II (Y): medium danger.

• Packing Group III (Z) : low danger.

Did you know you can use packaging certified for packing group X when transporting substances assigned to packing groups I, II or III

Read our article on Understanding UN Marks for more information.

Outer Packaging simply put is the outer protection of a composite or combination packaging. An example of an outer packaging type is fibreboard box, placed inside the outer packaging (fibreboard box) would be the inner receptacles or inner packaging, as well as any absorbent or cushioning material needed to contain and protect the inner(s) in the example .

Inner Packaging are packaging for which an outer packaging is needed in order to transport the dangerous goods safely. An example of this would be placing a glass bottle(s) (inner packaging) in to a Fibreboard Box (Outer Packaging) along with any absorbent or cushioning material needed to contain and protect the inner(s). Resulting in a Combination Packaging.

Combination Packaging is as it says, a combination of packaging for transport purposes. Combination packaging consist of one or more ‘inner packaging’ for example ‘glass bottles’ which are then secured in an ‘outer packaging’ for example ‘Plywood box’ the packaging chosen must be in accordance with the provisions set out in the relevant transport regulations.

Single packaging are packagings that do not require any inner packaging in order to perform their containment function during transport, and example would be UN approved Steel Drum or Jerrican.

Packagings consisting of an outer packaging and an inner receptacle constructed so the inner receptacle and the outer packaging form an integral packaging. Once assembled, it is an integrated single unit, it is filled, stored, transported and emptied as such. Examples of composite drums can been seen here.

All UN Approved packaging must be capable of withstanding normal conditions of transport, packagings are required to be tested under a quality assurance programme in order to ensure each packaging meets the requirements set out in a number of tests. These tests can vary depending on the Dangerous Goods to be contained and the type of packaging, examples of test criteria include: Leakproof Test, Stack Tests, Pressure Tests, Water Spray Tests and Drop Height Tests. There are instances where packaging containing dangerous goods does not need to be UN Approved and bear the UN Mark, for example Limited Quantity Packaging and Category B, Infectious Substances packaging, however, it does need to have demonstrated its capability to pass certain performance tests during production in order for it to be a suitable packaging for the dangerous goods. For more information read our performance test article.

Both 4G boxes and 4GV boxes are made of fibreboard and both provide good levels of protective support for dangerous goods when being shipped.

The packaging may look the same but there are subtle differences between the two which shippers may not be aware of. For example, there is often confusion about what inners can be used in a 4G box and what can be used in a 4GV box. We have written an article to help explain the main differences between 4G and 4GV packaging.

For 4G packaging the approved weight specified on the UN mark is the maximum gross weight of the entire fully assembled package, this includes inners and contents, cushioning, packaging accessories and the outer packaging itself

4GV allows for various non-specific inners, the permitted gross mass of inner packagings including substances shall not exceed one-half the gross mass of inner packaging used for the drop test. For instance, if the packaging was tested with 10kg of inner packagings (inner(s) & substance), then the approved (permitted) gross weight of inners would be 5kg. The remainder of the gross package weight allows for the weight associated with the cushioning and packaging accessories as well as the outer box itself. Read our understanding 4GV weight rules here

When required to be used as UN Approved packaging, 4G boxes can only be used to ship specific inner packagings – the same type that were approved at test stage, such as a specific Winchester bottle or a particular HDPE plastic bottle. The packaging supplier should be able to tell you which inners are approved for the 4G packaging in question and whether the complete package design is approved to hold solids or liquids or both. It’s worth noting that different inner packaging than those originally tested can be added to the UN approval, subject to verification by the testing authority. Depending on the difference in specification, the packaging certificate holder may be offered a deviation from a full test with reduced package testing such as limited drop tests.

There are other circumstances where different inners can be used in 4G packaging, for example when a UN certified box isn’t required but a ‘capable box’ for such goods is required, for example when shipping limited quantities or some lithium batteries types.

4GV packaging permit non-specific inner packaging, allowing different inners from those tested. Meaning you can choose the most suitable inner for your substance, ie. glass bottles, plastic bottles, jerricans, drums etc.

Class 1 and 7 substances/articles are subject to specific restrictions and criteria. Any shippers wishing to use fibreboard packaging for class 1 and 7 should seek additional consultation from the Dangerous Goods Packaging supplier.

4G boxes have been tested and approved with specific inners and specific substance types in relation to solids or liquids, you must check the manufacturers assembly sheet to see whether the 4G combination packaging can ship solids or liquids.

4GV boxes can be used for the shipment of liquids or solids in various suitable inner packaging as the testing methods provide approved of liquid or solids (subject to the inner packaging being suitable for the substance).

4G packaging has been specifically tested and approved for an individual packing group, the shipper must take note of the Packing Group stipulated within the UN specification mark and ensure they select 4G packaging that is suitable for the substance/article they wish to ship

4GV are tested and approved to PG I (X) standards. As they are approved for the highest degree of danger PG I (X), it means they can also be used for substances/articles of a lesser degree of danger packing groups II (Y) & III (Z).

Also remember that each 4GV box has a maximum gross weight limit that will vary from box to box. One of the special packaging requirements relating to weight for “V” variants is ‘the total combined gross mass of inner packagings shall not exceed one-half the gross mass of inner packaging used for the drop test’. Shippers should refer to the assembly instructions for the weight restrictions.

Shippers can refer to the assembly sheet that accompanies the packaging, this will inform the shipper of the correct way to assemble and pack the dangerous goods in 4GV and 4G packaging, it will include taping method, weight allowances, suitable inners and cushioning requirements.

If shippers are unaware that they should be packaging the box as per the assembly instructions they may inadvertently pack the goods incorrectly and would be in breach of the UN approval. Read our article on the 5 common mistakes made when packing 4G/4GV boxes.

4DV packaging are wooden boxes made of plywood, they offer a strong, rigid outer packaging for the shipment of dangerous goods

4DV boxes can be used to ship numerous dangerous goods including, lithium batteries. They are ideal for larger, heavier items or multiple fragile or delicate inners due to their larger box size and robust solid build.

Ranging from small plywood boxes to large plywood boxes, the plywood range allows a maximum permitted weight of 120kg (inners and substance) and up to a gross package weight of 280kg.

Vermiculite is the approved cushioning material that must be used in all Air Sea Containers 4DV boxes as it was the cushioning material used during the UN approval testing process of each 4DV box. It must not be replaced with alternative cushioning material.

The 4DV plywood boxes are delivered flat pack and easily assembled on site as and when needed. The wooden shipping boxes are assembled & closed using a locking tongue method, meaning no screws or nails are required. As 4DV wooden shipping boxes are collapsible and come flat packed they are cost effective for delivery costs, they are also three times lighter than a traditional wooden box of the same size reducing future shipping costs. The foldable/collapsible/flatpack feature means they have the benefit of 90% space saving for those with limited storage.

All our UN Approved 4DV plywood wooden boxes are certified for the transport of dangerous goods by air, road and sea.

We sell a range of Aluminium Bottles include lacquered lined and non-lacquered lined bottles.

Glass bottles suitable for shipping dangerous goods, including bottles for liquids and solids as well as bottles that are able to withstand temperatures of 140 °C and 180°C.

Plastic Bottles, Containers and Jars which are suitable for the transportation of solids and liquids.

Tinplate inners include lacquered lined and non-lacquered lined.

All our inner packaging can be used with our 4GV and 4DV outer packaging range. The vast majority of our inner packaging have also been tested and approved to be used with our 4G range. For ease, on each of our 4G product pages you will find a list all of the approved with inners relating that that 4G box.

Single packaging are packagings that do not require any inner packaging in order to perform their containment function during transport. It is worth noting that single packaging can be used as an inner or and outer to form combination packaging if combination packaging is required for the dangerous goods wanting to be shipped.

All our single packaging is UN Approved for the transportation of Dangerous Goods.

We have a range of UN approved single packaging from: Steel, Plastic, Tinplate, Fibreboard and Composite Drums to Aluminium and Plastic Bottles as well as a variety of Jerricans.

Lithium Metal Batteries and Cells

Batteries and cells that have lithium metal or lithium compounds as an anode.

They are non-rechargeable and you will often find lithium metal batteries in devices such as calculators, watches, car key fobs and cameras.

Lithium-Ion Batteries and Cells

These are secondary batteries (rechargeable) where the lithium is only present in an ionic form in the electrolyte. Lithium polymer batteries are also included in this category.

These rechargeable lithium-ion batteries can be found in mobile phones, laptops, tablets, power tools, ebikes and escooters to name a few.

Lithium batteries are classified in Class 9 – Miscellaneous dangerous goods as:

- UN 3090, Lithium metal batteries; or

- UN 3480, Lithium-ion batteries

or, if inside a piece of equipment or packed separately with a piece of equipment to power that equipment as:

- UN 3091, Lithium metal batteries contained in equipment; or

- UN 3091, Lithium metal batteries packed with equipment

- UN 3481, Lithium-ion batteries contained in equipment; or

- UN 3481, Lithium-ion batteries packed with equipment

Read our Beginners Guide to Lithium Battery Regulations here.

Limited Quantities are dangerous goods that when presented in smaller quantities have a reduced risk of harm to people, animals, property or the environment. This reduced risk allows for limited quantity shipments to be sent without extensively approved UN packaging.

We have a variety of LQ packaging available. You can choose from our 4G box only range which are suitable for a variety of your preferred inners. Or for a complete solution with proven capability performance you can select our 4G boxes including stabilisers suitable for specific inner types.

Temperature-controlled packaging is a type of packaging designed to maintain a specific internal temperature range.

It is often required for the following temperature sensitive products:

- Pharmaceuticals

- Foods

- Organic samples

- Chemicals

- Laboratory materials

Our Thermal Control range of qualified -20°C temperature controlled packaging is achieved when used with dry ice.

Our ISO Shipper range are qualified to maintain a constant temperature of between 2-8°C throughout transport using either gel or cool packs.

When combined with our UN approved packaging, you can also ship your dangerous goods or infectious substances in a temperature controlled environment.

All Class 6 – Infectious Substances (Division 6.2), are or will be assigned to one of the following UN Numbers;

UN2814, Infectious substance, affecting humans

UN2900, Infectious substance affecting animals

UN3549 Medical waste, Category A, affecting animals only, solid

UN3549 Medical waste, Category A, affecting humans, solid

UN3291, Clinical waste unspecified n.o.s or Biomedical waste n.o.s or Medical waste, n.o.s. or Regulated medical waste n.o.s

UN3373, Biological Substance Category B.

Infectious substances that come under Class 6 Infectious Substances (Division 6.2) are divided into 3 categories.

Category A; An infectious substance that if an exposure occurs when transported is capable of causing permanent disability, life threatening or fatal disease in otherwise healthy humans.

Category B; An infectious substance which does not meet the criteria for inclusion in Category A.

Exceptions; There are a number of exceptions listed in the regulations, for example; substances that are unlikely to cause disease in humans or animals, patient specimens where there is a minimum likelihood that pathogens are present, or medical equipment potentially contaminated with or containing infectious substances. You must refer to the relevant regulations to identify whether your substance falls under exceptions as some exceptions do require specific packaging when transporting. For more information read our steps to understanding Infectious Substances.

When transporting any of the UN numbers UN2814, UK2900, UN3549, UN3291, UN3373 you must adhere to the relevant packing instructions for the mode of transport(s) used.

UN2814 = P620

UN2900 = P620

UN3549 = P622 (ADR only)

UN3291 = P621

UN3373 = P650.

Infectious Substances that are classed as Category A UN2814, UN2900 or Category B UN3373 require triple packaging; this consists of:

- Leakproof primary receptacle(s)

- Leakproof secondary packaging

- Absorbent material

- Cushioning (if more than 1 primary receptacle, they must be individually wrapped)

- Rigid outer *UN approved packaging (*UN Approved required for Category A only).

UN3549 is forbidden via Air but ADR Packing Instruction P622 requires triple packaging consisting of inner, intermediary and outer packagings. The outer packaging must conform to UN packing group I performance level for solids.

UN3291 Packing instructions P621 does not follow the triple packaging system and other forms of packaging are allowed, for example a rigid Outer packaging – Drums, Jerricans & Boxes are acceptable provided that the packaging meets UN packing group II performance standards.

For more information read our article on How to ship Infectious Substances here.

Vermiculite packing material is used to protect inner packagings from impact & shock, acting as cushioning and absorbent in case of leakage.

Vermiculite is lightweight, inert (non-reactive) and is often used when transporting flammable corrosive and fragile materials

For more information read our article on What is Vermiculite here.

These white odourless chips are a light-weight and dust-free alternative to vermiculite and provide high level shock and impact protection to inner packagings during transport.

The loose fill is made from gm free starch and is compostable and provides better all round protection than polystyrene loose fill.

The biodegradable chips used in the ECO range of 4GV will dissolve in water, this is a key property in it being able to perform as a biodegradable product.

Users of 4GV Eco Range packaging should be aware that the cushioning material will remain fit for purpose under normal conditions of transport and if packed in the manner in which it has been approved.

Leakage from contents should be a consideration in the transport of dangerous goods, ensure inner packaging’s are closed correctly and there is sufficient absorbent and containment which can be supplied for this packaging.

If there is concern over the leakage of an inner packaging this should be addressed to ensure there is no scope for this to happen, using secondary means of closure should be considered depending on the relevant packing instructions.

The 4GV Eco Range combination packaging has been UN approved and is a reliable environmentally friendly package that if used correctly will perform as intended.

Expanded Polystyrene (EPS) is a fixed, closed cell, thermoplastic, foam material produced from solidified beads of polystyrene, which is polymerised from styrene monomer and contains pentane (an expansion gas) dissolved within the polystyrene bead.

Small amounts of gas are contained in each solid polystyrene bead which expands when steam (heat) is applied therefore forming closed cells of EPS. The expanded cells take up approximately 40 times the volume of the original polystyrene bead. Utilising a mould with a second heat treatment, sizeable EPS blocks can be moulded into tailored shapes.

EPS comprises 98% air and is one of the lightest packaging materials. As a result this puts minimal weight to packaging, therefore transport costs and fuel emissions are kept low. Read more here.

EPS makes dependable and effective protective packaging for a comprehensive range of goods owing to its durability.

EPS is recyclable and is being recycled by both consumers and businesses around the world. It is able to be recycled into diverse new materials including hardwood replacement for garden furniture and slate replacement for roofing tiles: Read more here.

Currently most of the EPS waste in the UK is collected and transformed into Extruded Polystyrene (XPS) insulation panels for the construction industry, this reduces the environmental impact of building: View the recycling facts here.

The International EPS Alliance (INEPSA) was formed in 1992 by EPS organisations from:

- Asia (AMEPS)

- Europe (EUMEPS)

- North America (EPS Industry Alliance)

To augment EPS recycling and environmental stewardship epsrecycling.org/inepsa

Information regarding the above EPS organisations can be found here:epsrecycling.org/contact

Availability, method of operation and access of EPS recycling can vary from country to country.

Contact information regarding EPS recycling in specific countries or regions can be found here:

www.epsrecycling.org/global-recycling

Within the UK there are 13 EPS recyclers, details of which can be found here: www.eps.co.uk/recyclers

Further information about EPS recycling can be found here:

Here you can find the Torque Values for our inner and single packaging. Torque Information Sheet

Quotes & Orders

If you have found a product(s) of interest on our website you can add it to the ‘My Quote’ basket via the item’s product page, once you have added all your products to the ‘My Quote’ basket, select ‘Request Quote’, our sales team will then email you a quote. Our turnaround is pretty quick and we aim to get quote out to you within a few hours.

If you are unsure about what product you require for your substance or article, call 0151 653 1500 or email uk@airseadg.com and one of our technical advisers will be happy to discuss the packaging requirements for your dangerous goods.

After you have received your quote and you are ready to place an order, we will require a purchase order in writing, please include any quotation or account references you have been given and send in to UK@airseadg.com

Email us by replying to the order confirmation stating your amends or call 0151 653 1500, be sure to have your order reference number ready, if possible, our team will amend your order and resend a new quotation. Please note; orders cannot be amended once dispatched.

If you would like to check the status of your order, please call 0151 653 1500 or email us by replying to the order confirmation and our team will be able to help.

If you have a problem with or haven’t received your order, please call 0151 653 1500 or email us by replying to the order confirmation and our team will be able to help.

Delivery

We deliver our products to customers all around the world, including Europe, America Africa and Asia. We have sales offices internationally who can handle local enquiries, for all other locations contact our UK head office. For more information see our locations map for a list of our sales offices.

Delivery cost will depend on the delivery location and the weight and dims of the items to be delivered.

Stock items ordered before 2pm will be delivered the next working day for UK orders. Deliveries for international orders vary depending on freight requirements. Contact us on 0151 653 1500 and we can advise you on the delivery timescales for your particular order.

If you haven’t received your order, please call 0151 653 1500 or email us by replying to the order confirmation and our team will be able to help.

Payment

If your company has an account with us and you have sent in a purchase order, you will receive an invoice for the goods. If you don’t have an account with us, we require a purchase order in writing and pre-payment before your order is dispatched.

Pre payments can be made via:

- Credit Card payments; call 0151 653 1500, Option 1 to make your payment.

- BACS payment; include your name and order number as a reference, please forward a copy of the receipt to uk@airseadg.com

We have several payment options available.

- BACS Payment

- Credit Card

- Credit Account

You can contact 0151 653 1500 to discuss your companies payment options.

Contact details

Contact Telephone Number: 0151 653 1500

You can also complete our Contact Us form.

UK Office Opening Hours: 9am to 5pm, Monday – Friday (excluding Bank Holidays).

Complaints

Please contact us on 0151 653 1500, Option 1 or email uk@airseadg.com and we will action your complaint straight away.

UK

UK