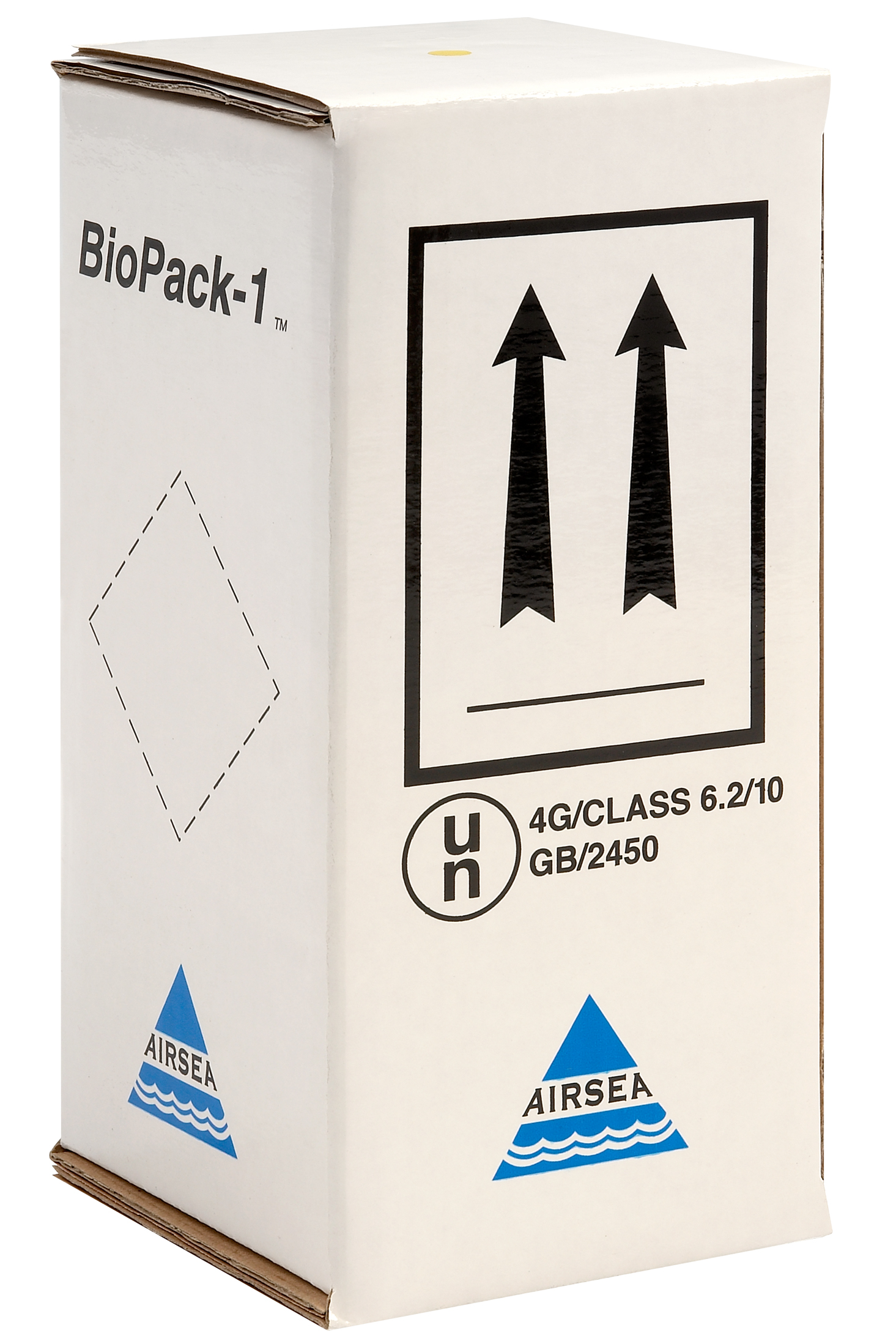

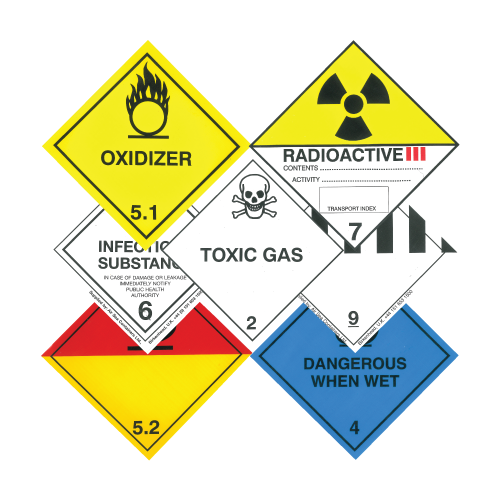

UN-approved packagings are subject to levels of advanced testing above those needed for standard everyday boxes and containers. The reason for this is because of the level of risks associated with shipping dangerous goods (also referred to as hazardous materials or hazardous substances).

The more dangerous the risk posed by the substance(s) being shipped, then the more strict a packagings compliance checks and requirements become.

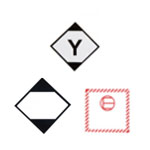

Packing Groups (PG), are assigned to hazardous material on the list of dangerous goods. There are 3 different packing groups. PG III or Z presents the lowest level of danger – packaging designed to permit PGIII substances require, in its most basic circumstances, a 0.8m drop test. Substances assigned to PG II or Y present a medium danger and packaging designed for PG II require a 1.2m drop test. Substances assigned to PG I or X are substances of high danger, and deemed as having a high level of risk, – packaging designed to carry PG I substances require a 1.8m drop test.

There are a multiple packaging performance tests which the UN packaging must pass before being awarded a UN certification and UN Mark.

At Air Sea Containers, we operate a UKAS accredited UN packaging testing laboratory which is authorised to test a range of UN packagings types to rigorous standards as set by the UN Recommendations on the Transport of Dangerous Goods Model Regulations. We also work closely with the UK’s Vehicle Certification Agency (VCA) Dangerous Goods Office (DGO) which are responsible for issuing UN packaging performance certificates and approvals. Once successful testing is completed, we submit our detailed report to the VCA DGO where they will assess our testing and issue the official UN certification.

Here we explain the most common packaging performance tests:

Drop Packaging Test

Whereby a number of test samples are required and are dropped from a particular height. The aim of a drop test is to subject packagings to circumstances that they may meet during transport, the packaging undergoes drop tests to simulate real-world scenarios where packages may fall from a certain height. These tests assess the packaging’s ability to protect its contents from damage or leakage when subjected to impact forces. Drop tests are conducted using the test criteria specified by the relevant transport regulatory bodies such as the United Nations Dangerous Goods Transport Regulations.

Certain packaging types require samples to be dropped in specific positions; i.e. fibreboard boxes require samples to be dropped on their top, bottom, sides and corner as to properly test the performance standards of the packaging. you can read more about combination packaging performance testing here.

Pressure Packaging Test

Dangerous goods often come into contact with different levels of pressure in the transport process; particularly when being sent via air. Therefore it may be a requirement for packaging to be able to withstand levels of pressure. 95kpa is a common example of a pressure that certain packagings may be required to withstand.

Stack Packaging Test

A stack test is performed using a predetermined load, calculated based on the package’s height, weight, and any inter-stacking features, to simulate the pressure exerted by a 3-metre-high stack. It is likely that at some point in the transport process that another package will be placed on top, therefore this test aims to ensure that packagings for dangerous goods are strong enough to withstand common conditions of transport.

Puncture Packaging Test

In a puncture test, packages are subjected to a cylindrical steel rod being dropped vertically in attempt to penetrate the package. For this test to pass, the primary receptacles used must contain any leakages. There is an allowance for the secondary packaging to be affected, providing the primary receptacles are not.

There are other forms of packaging tests that apply only to a small number of dangerous goods. These include:

- Hot Water Bath Test

- Leakproof test

- Leakage Test (Not the same as a leakproof test)

Information correct at time of publishing, 11th May 2018

Last updated 12/06/25

UK

UK