If you use UN combination packaging to transport your hazardous goods then you will be aware of the importance of assembling the packaging correctly.

To ensure the packaging can fulfill its capability and the integrity of the packaging and contents are not compromised, it is important to pack the box correctly as per the assembly instructions. If packed incorrectly, you risk invalidating the UN certification and the substance being compromised during transit. It is the shipper’s responsibility to ensure the assembly instructions are strictly followed.

The Importance of Following Assembly Instructions

In order to prove its capabilities and to gain UN certification, each UN packaging design undergoes vigorous testing to comply with test requirements set out in dangerous goods transport regulations. Tests include drop tests and stack tests, all 4DV packaging must be approved for PG I, so must pass a 1.8m drop test with glass bottles containing liquids.

The cushioning you use when assembling your 4DV packaging must be the same cushioning type used in the approval tests. For example, if it’s been tested with vermiculite, then you must use vermiculite. If alternative cushioning is used, it may not provide the same protection as the approved with cushioning. Not only will it invalidate the UN certification, but you also risk the inners and substances being compromised during transit. Again, shippers should consult the manufacturer’s assembly sheet to ascertain what cushioning should be used.

Just as important is the quantity of the cushioning material required in order to sufficiently secure and protect the inners from moving around within the 4DV box. Some cushioning types also act as the absorbent material hence the importance of ensuring you are using the recommended type and volume of cushioning. Usually, there is a minimum requirement of cushioning material for layering and spacing within the box. The assembly sheet will provide the shipper with information surrounding the quantity of cushioning material recommended for the 4DV box. It is worth noting that not all combination packaging requires cushioning but where it does, you must use it as per the assembly sheet.

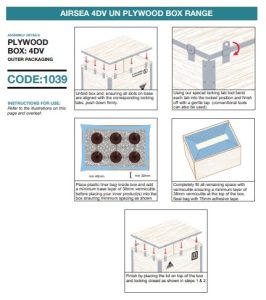

How To Assemble Air Sea’s 4DV Boxes

To assemble the box, unfold the box, ensuring all slots on the base are aligned with the corresponding locking tabs, push down the base firmly, bend each tab into the locked position, tap the tab securely in place using the tab locking tool.

Place the liner bag inside the box and add a layer of vermiculite at the bottom, to the minimum depth as stated on the assembly sheet before placing your suitable inners ensuring minimum spacing as shown on the assembly sheet. Completely fill all remaining space with vermiculite ensuring a minimum layer at the top of the box as stated on the assembly sheet. Seal the bag with the appropriate adhesive tape as stated on the assembly sheet.

Finish by placing the lid on top of the box and locking closed as with the base using the separately supplied tab locking tool.

Correct Assembly Matters

The importance of assembling the box as per the assembly instructions cannot be overlooked. The UN approved packaging must be assembled exactly as it was when it passed the UN testing process. If a shipper changes any of the components or packs the contents contrary to the assembly instructions, the packaging will be compromised and will not perform to its full capability.

Make sure you check the manufacturers assembly instructions to ensure that your packaging will not be compromised during transportation.

Air Sea’s packagings are unique and feature QR codes which when scanned provide assembly information including written step by step assembly instructions, assembly videos, package contents itinerary, weight restrictions, FAQs and more. This information aims to simplify the packing process for those organisations across a variety of industries who use Air Sea Containers’ UN packaging to ship dangerous goods, such as; biomedical, pharmaceutical, veterinary, petrochemical, food and drink industries.

Our aim is to help shippers transport dangerous goods safely around the world by supplying high quality compliant packaging and assembly instructions to make the process as simple as possible.

Contact us for a quote

US

US